Multi

Overview Product Description The CNC busbar processing machine is special for processing aluminum and copper busbars. It

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | BOBO |

| Maximum Bending Force | 300kn |

| Maximum Cutting Width | 150mm |

| Maximum Processing Width | 150mm |

| Maximum Processing Thickness | 12mm |

| Punching Range | 4.3-25mm |

| Maximum Punching Force | 300kn |

| Transport Package | Wooden Cage |

| Origin | China |

| Production Capacity | 10000 |

Product Description

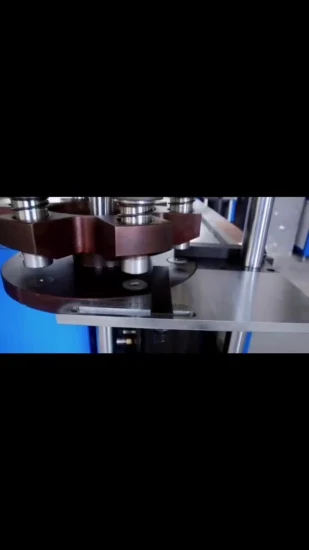

Product DescriptionThe CNC busbar processing machine is special for processing aluminum and copper busbars. It combines punching, cutting and bending units, and three units can work simultaneously. When operating, choose the appropriate processing unit to proceeding cutting, punching, fold bending, vertical bending, embossing, flatting, twisting.

Features1. The shearing unit adopts universal double-knife shearing, the notch is smooth and free of burrs

2. The hook-type open bending station is simple and convenient to operate, and can process special back-shaped small bending, embossing, vertical bending, etc.

3. The bending unit adopts horizontal processing, which is safer and more convenient during processing, and can complete U-shaped bends with a minimum size of 3.5MM.

4. The working stroke of each processing unit can be easily adjusted, reducing auxiliary processing time and improving production efficiency.

| No | Parameter | Data |

| 1 | Maximum punching force | 300kn |

| 2 | Punching range | 4.3-25mm |

| 3 | Maximum processing width | 150mm |

| 4 | Maximum processing thickness | 12mm |

| 5 | Maximum shear force | 400kn |

| 6 | Maximum shear thickness | 12mm |

| 7 | Maximum cutting width | 150mm |

| 8 | Maximum bending force | 300kn |

| 9 | Maximum bending width | 150mm |

| 10 | Maximum bending thickness | 12mm |

| 11 | Power | 3*4kw |

| 12 | Weight | 1400kg |

1. Q: What is the power supply of the machine?

A: The standard power supply in china is 380V, 3P, 50Hz. We also can customized accordingly.

2. Q: What information should the customer provide to get an accurate quotation from us?

A: The customer should provide the related technical requirements, drawings, pictures, industrial voltage, planned output, etc

3. Q: What is the payment term A: The payment term is 30% down payment, and 70% before shipment(T/T mode), we also accept other payment term, like L/C, DA, D/P etc

4. Q: What is the delivery time?

A: Normally the delivery time of the machine is 30 days after receive down payment.

5. Q: What is the warrantee period of the machine?

A: The warrantee period is one year since the date of B/L.

Packaging:

Stable wooden package protects machine from strike and damage.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

Shipping:

For LCL, we cooperated with reputable logistics team to send machine to sea port speedily and safely.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like

to have seamless cooperation with your forwarder at your convenience.