Bending Machine Upper Moulds, Press Brake Dies for Sheet Metal Works

Overview Product Description Use the right tools to achieve perfect bending results when air bending, embossing, and 3-p

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | XMC-P-123 |

| Manufacturing Technology | Automation Technology |

| Driving Motor Type | Permanent Magnet |

| Mold Cavity Technology | CNC Milling |

| Milling Speed | High Speed |

| Parts Detection Method | Geometric Detection |

| After-sales Service | 2 Years |

| Coating | Titanium Black Coating or by Custom |

| Segment | Available |

| Surface Tolerance | 0.02mm |

| Customize & Desigen Service | Available |

| Tool Refurbishment Service | Available |

| OEM & ODM Service | Available |

| Structure | Forging Froming |

| Hardness | 45-53 HRC |

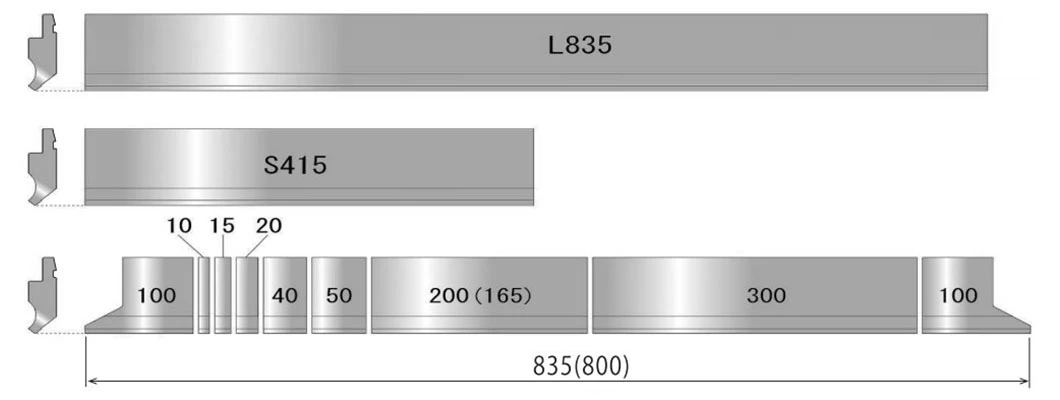

| Length | 719 835 mm or by Custom |

| Certification | CE, ISO9001 |

| Application Material | Steel Bar, Stainless Steel, Carbon Steel, Aluminum |

| Condition | New |

| Transport Package | Wood Case |

| Specification | by custom |

| Trademark | XINMECHAN |

| Origin | China |

| HS Code | 8207300090 |

| Production Capacity | 20000 PCS/Month |

Product Description

Product Description

Use the right tools to achieve perfect bending results when air bending, embossing, and 3-point bending. XINMECHAN's extensive range of high-quality press brake tools meets various bending demands. Our bending tools are capable of unleashing the full potential of the machine's features, press brake tooling is available for machines from 120KN to 30000KN, to ensure that your parts are always bent with utmost precision.

Advantages: 1. Fast and easy to configure tool lengths 2. Extremely accurate, fast, safe, and flexible 3. Suitable for all press brakes and all bending applications 4. For extreme precision and bending performance 5. Very high workload capacity and maximum durability 6. Very high-quality finish 7. Provides maximum long-term performance

Material and Hardness: Optimum materials: 1. 42CrMo4, tempered to 1100 - 1200 N/mm2 2. C45, tempered to 800 - 850 N/mm2 3. C45, 650 - 800 N/mm² Hardness: 52 - 55 HRCSurface Coating and Refinement: 1. No tool contamination while bending zink-coated sheets and aluminum 2. No ferritic infection at stainless steel 3. Less friction coefficient 4. Higher lifetime 5. Non-corroding 6. Minimized adhesion of material abrasion of the bent part

Product Parameters

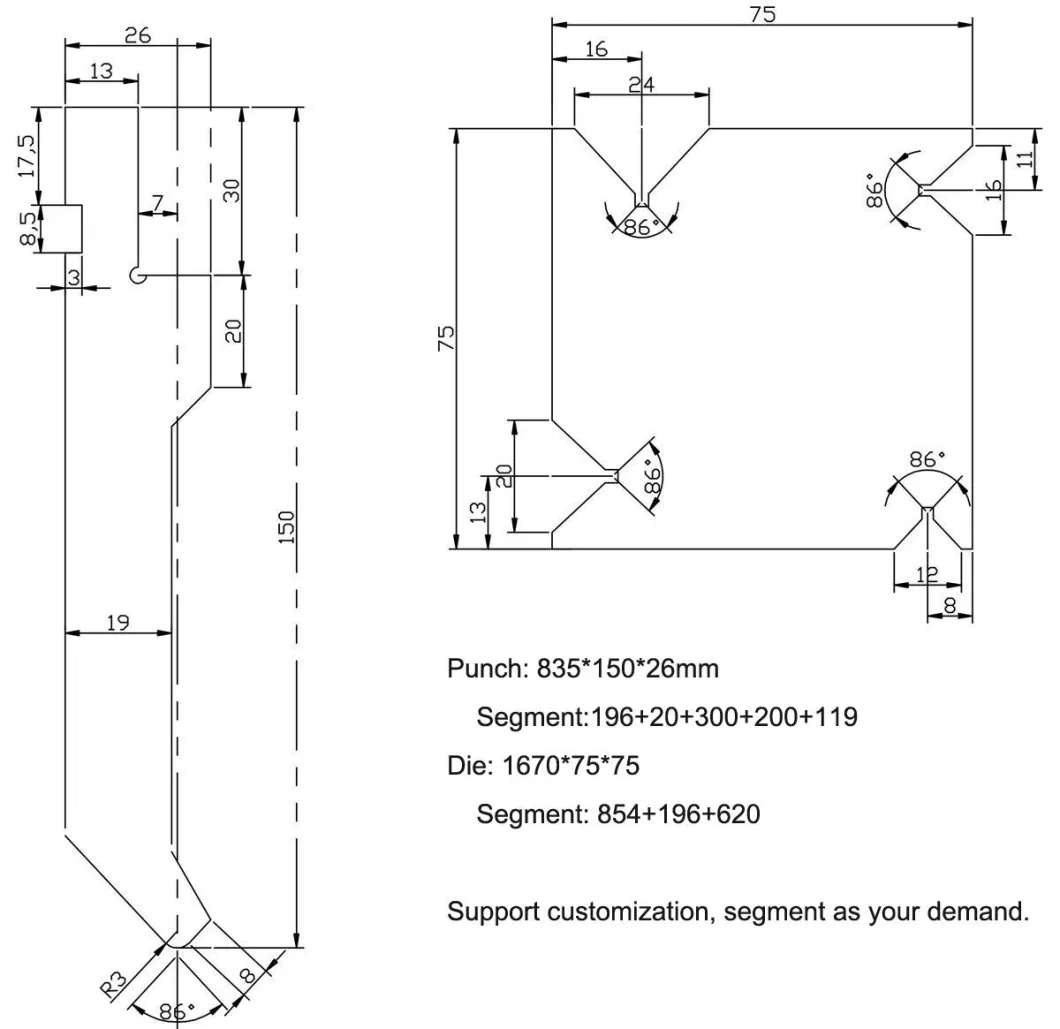

Please send us the drawing for accurate shape and size, refer to below picture.

The below sizes are for bending tools for some standard models of press brakes, for your reference. We also can make the bending punch/die by custom.

| MODEL OF PRESS BRAKE | UPPER DIE (MM) | LOWER DIE(MM) |

| 40T/2000 | 2000x70x18 | 2000x55x55 |

| 40T/2000 | 2000x80x18 | 2000x75x75 |

| 40T/2000 | 2000x90x30 | 2000x55x55 |

| 40T/2000 | 2000x150x26 | 2000x55x50 |

| 63T/2500 | 2000x85x28 | 2500x70x70 |

| 63T/2500 | 2500x150x25 | 2500x65x65 |

| 63T/2500 | 2500x85x28 | 2500x55x55 |

| 63T/2500 | 2500x100x20.5 | 2500x70x70 |

| 80T/3200 | 3200x80x18 | 3200x95x95 |

| 100T/3200 | 3200x150x26 | 3200x95x95 |

| 100T/3200 | 3250x86x28 | 3250x75x75 |

| 100T/3200 | 3200x72x30 | 3200x100x100 |

| 100T/3200 | 3250x80x25 | 3250x95x95 |

| 100T/3200 | 3200x85x25 | 3200x75x75 |

| 100T/3200 | 3200x80x25 | 3200x95x95 |

| 160T/3200 | 3200x90x56 | 3200x110x110 |

| 160T/4000 | 4000x80x25 | 4000x110x110 |

| 160T/4000 | 4000x90x30 | 4000x110x110 |

| 160T/4000 | 4000x134x34 | 4000x120x120 |

These are only some typical sizes. More are available. Please contact us for further information.OEM service is also available. Just send us the drawing. Our proficient engineers will take care of the rest.

Standard mold:1. When ordering a standard mold, select the mold's shape. 2. Provide the total length, angle, sharp R, die height, etc.3. The mold that needs to be divided can be divided into dimensions.The special bending forming mold:1. Provide the cross-section shape drawing of the product workpiece.2. Provide bending machine manufacturer, tonnage, length, and other relevant data.3. Provide product material, plate thickness, and other data.4. Put forward product requirements (such as scratch, R angle size, parallelism, and straightness).5. Provide product materials (for mold test).6. If there is any difficulty in selecting the mold, please consult us.

Certifications

Packaging & Shipping

Company Profile

With more than twenty years of experience in manufacturing, XINMECHAN provides press brake tooling of outstanding quality. We select high-quality raw materials and promise a competitive factory price with good performance. Every technical index reaches the international standard. Our press brake tooling has passed the ISO 9001 and CE quality certification. We supply professional before and after-sale service to each piece with a short delivery time and safe packaging.After Sales Service

Pre-sales services, supply customization:We provide customers with the best possible process solutions, technical advice, samples to test, model selection, and other consulting service.In-sale services, provide all aspects of technical support:We design tailor-made training programs for you, including equipment operation, product maintenance and maintenance, troubleshooting, safety operation, and other aspects of training.After-sales service is perfectly and timely:We guarantee 10 hours to respond to customer demand, free maintenance during the warranty period, life-long maintenance, timely provision of spare parts, remote diagnosis, regular visits, and other services.FAQ

Q1. How to get the most suitable product and best price?Please tell us what you want, the size/dimension, drawing, applied bending material, raw material, and other information.Q2. Can you help to design or draw the bending punch/die we need?Yes, we can, please send us the drawing of your workpieces, applied bending machine details, required raw material, and other information.Q3: What is your advantage?1. End manufacturer with competitive price.2. Different raw materials for you to choose from, we can give professional suggestions to you.3. Various blades for you to choose from, OEM&ODM are supported.4. High wear resistance and waterproof.5. Short delivery time & safe packaging.Q4: How long is your delivery time?Generally, it is 3 days if the goods are in stock. or it is 15-45 days if the goods are not in stock, it is according toquantity.

Related Products

-

![Batch Processing 1250*2500mm CNC Turret Pressing Punching Forming Perforating Machine for Aluminum/ Steel/ Copper/ Stainless Plate and Pipe]()

Batch Processing 1250*2500mm CNC Turret Pressing Punching Forming Perforating Machine for Aluminum/ Steel/ Copper/ Stainless Plate and Pipe

-

![Copper Aluminum Stainless Steel Metal Pipe Bender Machine Afford Design Exhaust Tube Bending Dies]()

Copper Aluminum Stainless Steel Metal Pipe Bender Machine Afford Design Exhaust Tube Bending Dies

-

![Stamping Die Processing Non]()

Stamping Die Processing Non

-

![CNC Hydraulic Busbar Processing Machine with Bending, Punching and Cutting]()

CNC Hydraulic Busbar Processing Machine with Bending, Punching and Cutting